Many bigger buildings in Australia, together with high-rises, bridges, harbours, and industrial vegetation, are constructed utilizing pile foundations. Piles are the lengthy columnar parts, sometimes product of metal, concrete or timber, utilized in deep foundations to make sure structural stability. They’re generally put in in soils with inadequate load-bearing capability, in coastal areas with sandy and waterlogged floor, and to successfully distribute hundreds in large-scale developments.

Piling methods are categorised by how they’re put in into the soil. For foundations in non-cohesive and contaminated soils and areas with excessive water tables, pile driving tools successfully pushes pre-cast concrete, metal, composite or timber piles to bigger depths with hammering or vibrations. Piles will be assembled on-site with non permanent or everlasting casings or off-site as pre-cast piles.

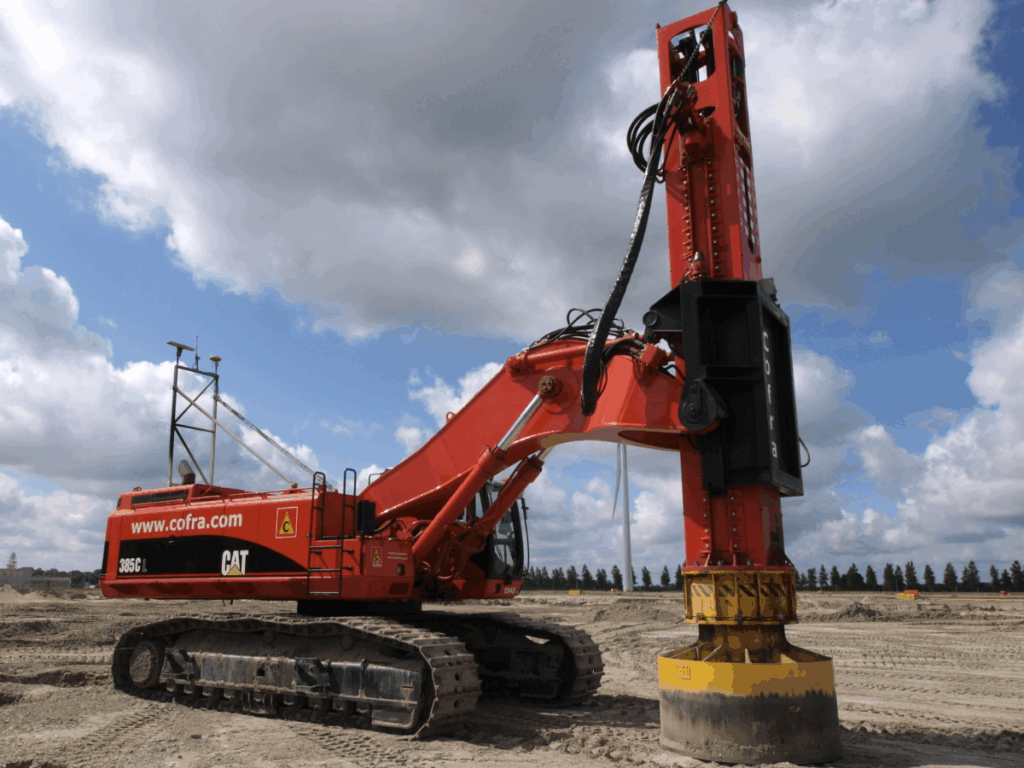

Driving piles to bigger depths requires the usage of pile drivers. These will be categorised into percussion, vibratory and hydraulic.

Percussion

Percussion pile drivers or hammers are designed to ship a heavy blow to the highest of the pile. The forms of hammers embrace:

Drop hammers

Also referred to as a gravity hammer, this is among the easiest and oldest forms of pile-driving tools. It consists of a heavy ram, sometimes a block of iron, which is dropped from a rig hooked up and suspended by a rope or winch. The affect of the falling weight drives the pile into the bottom. Drop hammers are generally seen in smaller operations, with elevated versatility throughout completely different initiatives by various the drop peak and the burden of the ram.

Air hammers

Air pile hammers use compressed air to repeatedly strike piles. They’re favoured for his or her versatility and compatibility with different tools, together with cranes and excavators, and that they work equally nicely with piles in several supplies. The hammers come as single-acting, which use steam strain to raise the hammer (which then drops below its personal weight), and double-acting air hammer, with air strain lifting and driving the hammer towards the pile. This provides extra power and achieves a shorter stroke. Air hammers are used for his or her excessive affect power, particularly in tougher floor, and as a viable different to vibratory pile drivers, with the flexibility to drive piles to bigger depths.

Diesel hammers

These are self-contained pile driving tools, utilizing the power generated by a diesel engine to repeatedly drive a hammering ram and cylinder mechanism. Diesel pile hammers require much less auxiliary tools (reminiscent of exterior energy sources), which means decrease buy and working prices, in addition to smaller footprints than comparable air hammers. Excessive-powered, dependable and sturdy, they’re utilized in demanding development settings.

Vibratory

Vibration hammers use high-frequency vibrations to drive piles into the bottom or extract them from the soil. They work by creating vertical vibrations through rotating eccentric weights, which then switch onto the piles. This loosens up compacted soil, decreasing its friction and resistance, permitting piles to sink into the bottom below their very own weight. To make sure vibrations are stored inside the system and never transferred to supporting cranes or excavators, vibratory hammers use vibration suppressors. Furthermore, hydraulic clamps guarantee piles are secured and straight throughout driving or extraction.

Vibratory pile hammers use energy from hydraulic motors for quick operation. They’re additionally extremely adaptable to drive numerous forms of piles and in demanding circumstances, particularly in underwater use, for example, when driving bridge helps or turbine foundations into the seabed. And the truth that they’re considerably quieter than percussion hammers makes them supreme for residential and business use.

Hydraulic

These are extra highly effective, extra versatile and quieter alternate options to diesel pile hammers. Hydraulic pile drivers work utilizing pressurised hydraulic fluid to raise and decrease a ram. Improved management methods permit operators to set the exact stroke peak, affect power, and driving velocity, which means these pile hammers are suited to driving metal and concrete piles reminiscent of beams and pipes, in addition to timber and pre-cast pile sheets with greater precision and at distinctive speeds of as much as 80 blows a minute. Apart from decrease noise ranges, they’re additionally most popular for his or her decrease environmental affect, with fewer pollution.

Purposes and Industries

Pile drivers are seen in purposes the place there’s a necessity for steady deep foundations. The instruments guarantee speedy set up, excessive affect power and constant productiveness in operations of various scope. This consists of:

- Constructing development: Pile drivers are vital for steady foundations supporting business buildings. together with skyscrapers, workplace buildings, purchasing malls, hospitals, factories, warehouses and extra. Piles are moreover pushed into poor or waterlogged soils when constructing foundations for residential properties.

- Infrastructure initiatives: Piles are pushed deep into the bottom to succeed in steady, rocky substrate, guaranteeing excessive load capability in main infrastructure initiatives starting from bridges, tunnels and overpasses, to roads and railway traces. In areas with difficult soil circumstances, pile drivers additionally set up piles throughout the development of retaining partitions and sound obstacles.

- Marine/offshore purposes: Unfastened waterbeds require piles to make sure that wharves, docks, and piers stay steady and supported by tougher floor at bigger depths. Piles additionally present structural integrity to offshore oil rigs and gasoline platforms, in addition to controlling water ranges and offering boat entry in marinas.

- Renewable vitality: On and offshore wind farms, large-scale photo voltaic operations and different renewable vitality installations profit from the help and diminished vibrations of pile foundations.

Advantages of Pile-Pushed Foundations

In comparison with in-situ bored or auger-drilled piles, pushed piles guarantee quicker set up instances with speedy load-bearing capability. They’re the one basis kind appropriate for difficult soils, together with expansive clay, free sand and areas with excessive water tables.

Putting in pushed piles compacts the soils, guaranteeing excessive basis stability and energy, with excessive resistance to water infiltration, corrosion and deteriorating soil circumstances. The prevents soil settlement and vibrations and leads to the next resistance to lateral forces. Pushed piles additionally usually contain decrease web site affect.

The scope and specifics of your venture are the principle issues when selecting the best pile driving hammers. Soil circumstances will affect shopping for decisions, with vibratory hammers extra suited to non-cohesive and free soils, whereas diesel and air hammers for extra compacted soils. Whereas all pile drivers work with quite a lot of supplies and pile sorts, in addition they think about how hammers deal with metal, concrete or timber piles, and the ancillary tools (cushions, helmets, driving caps, and so on.) required to minimise part harm or guarantee correct driving power. This may add to general prices, however will guarantee appropriate operation with minimal downtime.

Different issues are how appropriate the tools is to hammer piles to the specified depths and whether or not they have the required load capability to make sure protected, steady and timely-installed pile foundations. When selecting tools, additionally think about web site rules to minimise disturbance and extreme noise; worksite entry to evaluate tools measurement and transportation, and venture scale and whether or not heavy-duty tools gives a greater stability between efficiency and general prices.